When selecting the appropriate bag as a form of industrial and bulk packaging, it is not only about the appearance or cost. The actual performance of the packaging will be based on technical aspects like GSM and fabric strength. Failures in packaging may result in destruction of the products, spillage, loss during transport, and even safety hazards, when the decisions are made wrong.

That is why the businesses in the spheres of agriculture, construction, chemicals, and food processing use PP woven bags, which are also designed in the way they are utilized. The knowledge of the interaction between GSM and fabric strength enables the buyer to make a wise decision that is sensitive to durability, cost and long term reliability.

This guide offers the ability to select the appropriate woven polypropylene bags, depending on the GSM and cloth strength, without misunderstanding or over-engineering.

What Are PP Woven Bags and Why Are They Widely Used?

PP woven bags are packaging bags created out of tapes of polypropylene which are woven to create a breathable and strong fabric. These bags are characterized by durability, flexibility and the capability of carrying heavy loads during demanding conditions.

They are common in the packing of food grains, sugar, cement, fertilizers, chemicals, animal feed and raw materials used in industries. pp bags are more tear and moisture resistant as well as rough handling resistant compared to the traditional packaging materials.

The modern pp woven sacks may also be laminated or printed and they are also suitable in both functional and branding purposes. This flexibility is what makes them a favorable choice to both be used locally and also as export.

What Does GSM Mean in PP Woven Bags?

GSM (Grams per Square Meter) can be defined as the weight of the piece of fabric, with which the bag is made. Simply, it refers to the heaviness or the density of the woven material.

A higher GSM generally means:

- Thicker fabric

- Better load handling

- Higher material usage

But not only GSM defines overall quality. Two pp woven fabric bags of the same GSM may have a very different behavior based on the way the fabric had been woven and the raw material.

Common GSM Ranges and Their Applications

- 40–60 GSM: Light-duty packaging for low-weight products

- 70–90 GSM: Medium-duty packaging for grains, seeds, and food products

- 100–120 GSM and above: Heavy-duty industrial and construction materials

The right GSM will assist in saving unnecessary expenditures and, at the same time, provide sufficient protection.

How Is Fabric Strength Different from GSM?

When GSM is used to measure weight, the use of fabric strength measures performance. Fabric strength is the capacity of the woven fabric to withstand tearing, stretching and bursting whenever put under load.

The strength of fabrics is dependent on a number of factors:

- Tape width and thickness

- Density of weaving (ends per inch).

- Polypropylene raw material quality.

- Manufacturing precision

A smaller GSM bag can be produced with great fabric strength provided it has been engineered well. That is why consumers with experience consider both parameters rather than using GSM.

How to Choose the Right GSM for PP Woven Bags?

Selecting the right GSM depends on how the bag will be used, handled, and stored.

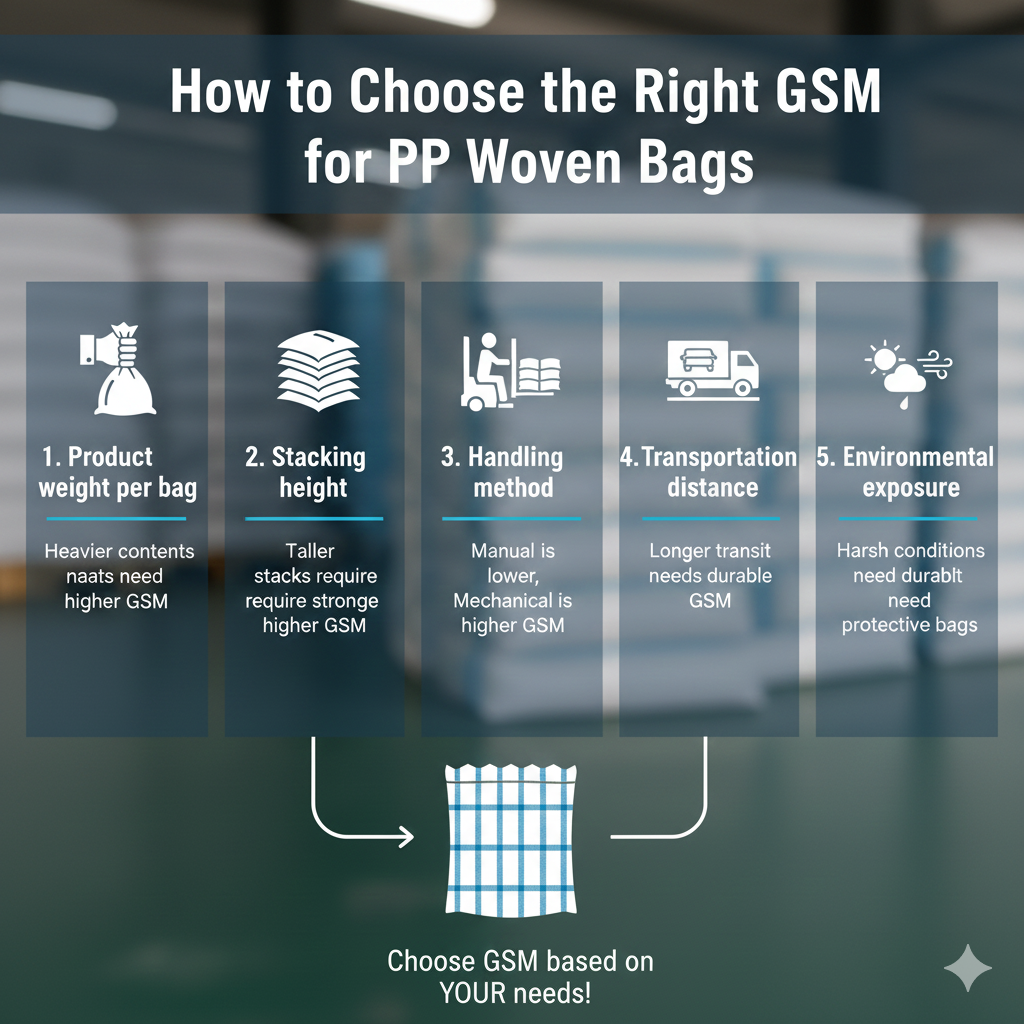

Key Factors to Consider

- Product weight per bag

- Stacking height during storage

- Handling method (manual or mechanical)

- Transportation distance

- Environmental exposure

To take a case, the GSM might not be so great in agricultural products that have been kept in warehouses as opposed to cement bags that are shipped over long distances. The manufacturer of the pp woven bags will also be a reliable manufacturer who will suggest the most efficient GSM in terms of the actual use of the materials and not over specifying the material.

How to Select PP Woven Bags Based on Fabric Strength?

Fabric strength becomes critical when bags are exposed to repeated handling, vibration, or heavy stacking.

Important Strength Parameters

- Tensile strength: Resistance to pulling forces

- Bursting strength: Ability to withstand internal pressure

- Seam strength: Durability of stitched or heat-sealed edges

Laboratory tested strengths are frequently demanded by exporters and bulk purchasers so that the same standards are produced throughout a large purchase. Powerful fabric eliminates the chances of tearing during transportation hence has direct effects on supply chain reliability.

GSM vs Fabric Strength: Which Is More Important?

It is also among the most frequently asked questions by the buyers.

The solution is simpler than that: both matter, however, balance matters more.

The cost and thickness depend on GSM, whereas the strength of the fabric affects the performance on the ground. The bag that is unnecessarily high GSM, yet the weaving is not of a high quality can also break. Alternatively, fabric strength that will be optimized and with controlled GSM will provide better value.

The most effective solution is to align GSM with the fabric strength according to the usage and not the best specification as a random option.

Choosing PP Woven Bags for Different Industries

Different industries have different packaging demands, and selecting the right combination of GSM and strength ensures long-term efficiency.

Agriculture and Food Grains

- Moderate GSM with high tear resistance

- Breathable fabric to prevent moisture buildup

- Suitable for rice, wheat, maize, and pulses

Cement and Construction Materials

- High fabric strength to withstand heavy loads

- Often combined with lamination for moisture protection

- Requires consistent quality across batches

Chemicals and Fertilizers

Strong seams and high bursting strength

Chemical-resistant lamination options

Secure handling during transport

Retail and Branded Packaging

- Use of printed pp woven bags

- Balanced strength with visual appeal

- Custom sizing and branding

What Role Does Lamination Play in Fabric Strength?

An additional barrier is laminated pp woven bags which have a bonded polypropylene film on the woven fabric. Although lamination does not make fabric strength any more important, it improves:

- Moisture resistance

- Print quality

- Product safety

In the case of product that is prone to any humidity effects, lamination is necessary despite the fact that GSM and strength of fabrics have been maximized.

Common Myths About GSM and Fabric Strength

There is still a great proportion of buying customers who use outdated assumptions when choosing packaging.

- Myth 1: Higher GSM always means stronger bags

- Reality: Strength depends on weaving quality and raw material, not just weight.

- Myth 2: All woven bags perform the same

- Reality: Manufacturing standards vary widely between suppliers.

- Myth 3: Recycled material cannot offer durability

- Reality: Controlled recycled blends can deliver reliable performance when processed correctly.

The knowledge of these myths assists buyers not to incur avoidable expenses and bad packaging choices.

How Manufacturers Ensure Consistent Quality in PP Woven Bags

A professional woven bags manufacturer follows strict quality control processes at every stage of production.

This includes:

- Raw material inspection

- Tape extrusion monitoring

- Controlled weaving density

- Strength and load testing

- Visual and dimensional checks

Large-volume purchases and exporters in particular are very sensitive to consistency because they require the standardization in packaging quality.

Why Choosing the Right PP Woven Bags Manufacturer Matters

It is not only specifications that give your packaging the success that it deserves, but rather, expertise. An experienced pp woven bags manufacturer understands how GSM and fabric strength interact under real-world conditions.

This is because such manufacturers do not impose unwarranted specifications. Instead, they focus on:

- Application-based recommendations

- Economical consumption of materials.

- Specialized solutions within industries.

This will make the buyers get packaging that works well yet will not cost excessively.

How Oberon Polypack Ensures Quality PP Woven Bags

As an experienced pp woven bags manufacturer, Oberon Polypack follows strict quality standards at every stage of production.

Key practices include:

- Use of premium-grade polypropylene raw materials

- Custom GSM and fabric strength options

- Advanced weaving technology for uniform strength

- Rigorous quality testing before dispatch

This focus on precision and reliability ensures that customers receive packaging solutions tailored to their specific industry needs.

Final Thoughts: Making an Informed Packaging Decision

Choosing PP woven bags by GSM and fabric strength is not complicated when you understand the fundamentals. GSM defines the weight and thickness, while fabric strength defines performance and durability.

The best solutions of packaging are those that balance the two depending on how they are to be used, handled and the environment they will be operating under. Through collaboration with an established producer and paying attention to actual needs, companies will be able to attain safer transportation, minimal losses, and sustainable value.

Taking time to make the appropriate choice of the woven polypropylene bags eventually results in better running of operations as well as better supply chains.

Frequently Asked Questions (People Also Ask)

What is the ideal GSM for PP woven bags?

The ideal GSM depends on product weight and usage. Medium GSM is suitable for most agricultural products, while heavy materials require higher GSM.

How much weight can PP woven bags hold?

Weight capacity depends on both GSM and fabric strength. Properly engineered bags can safely hold heavy industrial loads.

Is higher GSM always better?

Not necessarily. Fabric strength, weaving quality, and application matter just as much as GSM.

How can I check the strength of PP woven bags?

Tensile strength testing and load trials are the most reliable methods.

Which PP woven bags are best for heavy materials?

High-GSM, well-woven, laminated pp woven sacks offer the best performance for heavy-duty applications.