Packaging is important in the security of products, loss reduction, and brand awareness. Among various industrial packaging solutions, pp woven bags have become one of the most reliable and widely used options across multiple sectors. They are customizable and durable, and cost efficient, thus they fit both the domestic and export markets.

This complete guide explains everything you need to know about PP woven bags, from raw materials and manufacturing processes to types, applications, and how to choose the right manufacturer.

What Are PP Woven Bags?

PP woven bags are industrial packaging bags made from woven polypropylene fabric. Polypropylene is a thermoplastic polymer that is associated with strength, lightness, and lacks resistance to moisture and chemicals.

Woven, polypropylene bags on the other hand, are made by weaving the flat polypropylene tapes into a tougher fabric as opposed to the normal plastic bags. This structure enables them to have increased load-bearing capability and increased tear resistance.

What are PP woven bags used for?

Some of the agricultural products, cement, fertilizers, chemicals, food grains, sugar, and construction materials are usually packed in these bags. They are versatile in the sense they can be used to process lightweight and heavy packages.

Raw Materials Used in PP Woven Bags Manufacturing

The quality of PP woven bags largely depends on the raw materials used during production. The base material is made up of high-grade polypropylene granules.

Other additives are usually combined to add performance. UV stabilizers guard bags against the effects of sunlight whereas color masterbatches ensure uniform and appealing colors. Anti-slips are added to enhance handling during the stacking and transportation.

With high-quality raw materials, the fabrics are stronger, last longer and perform well in most applications.

Which raw material is used to make PP woven bags?

Polypropylene granules are the primary raw material used in manufacturing PP woven bags due to their durability and flexibility.

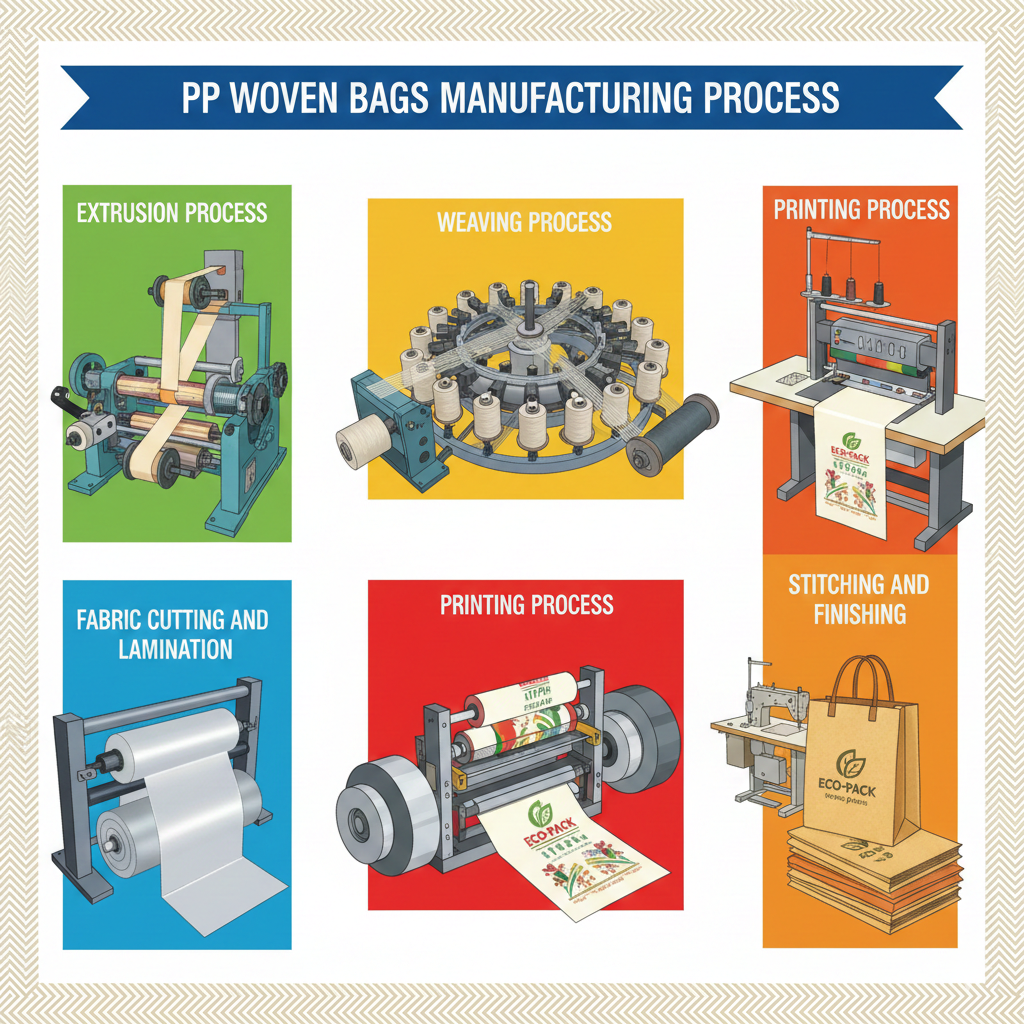

Step-by-Step PP Woven Bags Manufacturing Process

Understanding the manufacturing process helps buyers evaluate product quality and supplier reliability.

Extrusion Process

The process starts with melting polypropylene granules in an extruder. The molten polymer is converted into thin films and then slit into flat tapes. These tapes are stretched to increase tensile strength.

Weaving Process

The stretched tapes are fed into circular or flat looms. Here, the tapes are woven together to form fabric. The weaving pattern and density directly affect the strength and durability of the final bag.

Fabric Cutting and Lamination

Once the fabric is ready, it is cut according to the required bag size. Lamination can be applied to make the fabric moisture-resistant. Laminated pp woven bags are preferred for products that need protection from humidity and dust.

Printing Process

Branding and product information are added using flexographic printing. High-quality printed pp woven bags improve brand recognition and provide essential handling instructions.

Stitching and Finishing

The final stage includes stitching, hemming, valve fixing, and quality inspection. Each bag is checked for strength, dimension accuracy, and print clarity before dispatch.

Understanding GSM in PP Woven Bags

GSM (grams per square meter) is one of the most important parameters when selecting PP woven bags. It determines the density and sturdiness of the woven fabric.

Greater GSM bags are able to hold heavier items whereas the lower GSM bags can be used to carry lighter products. The appropriate choice of GSM provides maximum cost-performance ratio.

What GSM is best for PP woven bags?

The ideal GSM depends on the application. Agricultural products may require medium GSM, while cement and chemicals often need higher GSM for safety.

Types of PP Woven Bags Available in the Market

Different applications require different bag constructions. Below are the most common types used across industries.

Plain PP Woven Bags

These are uncoated and economical. They are widely used for grains, fertilizers, and minerals where moisture protection is not critical.

Printed PP Woven Bags

Printed pp woven bags allow high-quality branding using flexographic or rotogravure printing. These are ideal for retail packaging and brand visibility.

Laminated PP Woven Bags

Laminated pp woven bags feature an additional coating that provides moisture resistance, better appearance, and longer shelf life.

BOPP Laminated PP Woven Bags

BOPP laminated pp woven bags offer premium visual appeal with photo-quality printing. They are commonly used in food, seeds, and branded commodity packaging.

How Fabric Strength Impacts Bag Performance

The strength of the fabric is the strength that defines the amount of weight that the bag can hold without breaking or deforming. It relies on the width of tape, denseness of the weaving as well as GSM.

Durable cloths deter leakage of the product, minimise transportation losses, and enhance the efficiency of storing. Fabric of low quality can cause a fall of the bag which can cause both loss of money and safety risk.

How strong are PP woven bags?

High-quality PP woven bags are capable of carrying heavy loads when manufactured using proper GSM and weaving standards.

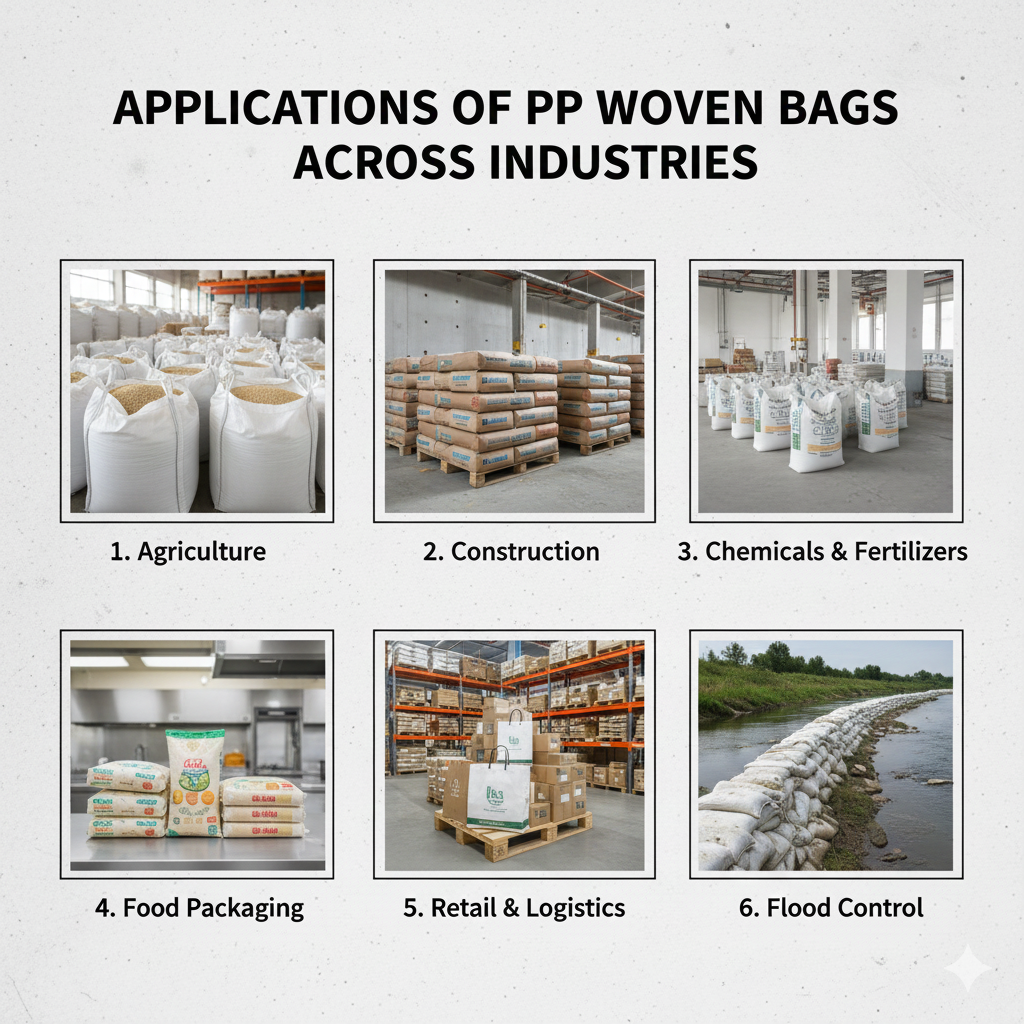

Applications of PP Woven Bags Across Industries

PP woven bags are used across a wide range of industries due to their adaptability and strength.

They are applied in agriculture in seeds, grains, animal feeds and also fertilizers. They are used in the construction industry in cement, sand and minerals. They are used in the packaging of powdered and granulated materials in safe ways by the chemical manufacturers.

Food industries use food-grade pp bags for sugar, rice, flour, and salt. They are also used in retail and logistics industries to do bulk packaging and storage.

Customization Options Offered by Manufacturers

Customization is one of the key advantages of PP woven bags. A reliable pp woven bags manufacturer offers multiple customization options to meet specific business needs.

These consist of differences in size, color preferences, printing and lamination and the use of UV bags to store them outside. Personalized bags would enhance functionality as well as brand equity.

Working with an experienced woven bags manufacturer ensures consistent quality and timely delivery.

Quality Standards and Certifications to Look For

Quality assurance is essential when sourcing PP woven bags. Manufacturers should follow strict quality control procedures throughout the production process.

Certifications such as ISO standards and food-grade compliance indicate adherence to industry norms. Quality checks include tensile strength testing, weight consistency, and visual inspection.

How to identify high-quality PP woven bags?

Check fabric strength, stitching quality, print clarity, and certification compliance before finalizing a supplier.

Environmental Impact and Sustainability

PP woven bags are reusable and recyclable, making them more sustainable than single-use plastic alternatives. They have a long life reducing packaging waste and minimizing the rate of replacement.

Most of the manufacturers are embracing environmentally friendly manufacturing processes with optimization of the use of material and reducing waste in the production process.

How to Choose the Right PP Woven Bags Manufacturer in India

India is a big source of PP woven packaging solutions. Choosing the right pp woven bags manufacturer in India requires careful evaluation.

Seek production capacity, quality control measures, personalization and experience in the industry. A reliable pp woven bags supplier should offer consistent quality, competitive pricing, and timely support.

Firms such as Oberon Polypack have concentrated in high quality production and manufacturing processes in order to satisfy various needs in the industry.

Cost Factors in PP Woven Bags Manufacturing

The cost of PP woven bags depends on multiple factors, including raw material prices, GSM, bag size, printing complexity, and lamination type.

Bulk orders tend to lower unit price and customized printing and a higher GSM might also raise the prices. The knowledge of these factors assists the businesses to make viable purchasing choices.

Conclusion: Why PP Woven Bags Are a Smart Packaging Choice

PP woven bags offer a perfect balance of strength, flexibility, and cost efficiency. They are a stable choice of packaging due to their organized organization of manufacturing process, customization of features and broad scope of their application in industrial processes.

GSM, fabric strength, and type of bags make businesses to choose the appropriate type of packaging that fits them. Partnering with an experienced pp woven bags manufacturer ensures long-term value, consistent quality, and operational efficiency.

Frequently Asked Questions About PP Woven Bags

Are PP woven bags waterproof?

Laminated variants offer good resistance to moisture.

Can PP woven bags be reused?

Yes, they are designed for multiple uses under normal conditions.

Are BOPP laminated bags suitable for branding?

Yes, bopp laminated pp woven bags provide excellent print quality and visual appeal.

Do PP woven bags support heavy loads?

Yes, when manufactured with appropriate GSM and fabric strength.