Introduction to BOPP Bags

In today’s competitive and fast-moving packaging industry, businesses are constantly looking for solutions that offer durability, visual appeal, and cost efficiency. This is where BOPP bags have emerged as a preferred choice across multiple sectors. From agriculture and food packaging to chemicals and retail products, BOPP bags play a crucial role in protecting goods while enhancing brand visibility.

Understanding the Types of BOPP Bags is essential for manufacturers, distributors, and brand owners who want packaging that aligns with their product requirements and market expectations. Each type of BOPP bag is designed with specific features that cater to different storage, transportation, and marketing needs.

Over the years, BOPP packaging has evolved beyond basic utility. With advancements in printing technology and material engineering, these bags now offer high-quality graphics, excellent moisture resistance, and impressive load-bearing capacity. This combination makes them ideal for both industrial and consumer-facing applications.

In this comprehensive guide, we will explore the different Types of BOPP Bags, their features, benefits, and applications. Whether you are choosing packaging for food products, agricultural commodities, or retail goods, this guide will help you make an informed decision based on performance, functionality, and long-term value.

What Are BOPP Bags?

.png)

BOPP bags are packaging bags made using Biaxially Oriented Polypropylene (BOPP) film laminated onto woven polypropylene fabric. This combination offers exceptional strength along with superior print clarity.

The biaxial orientation process stretches the polypropylene film in both machine and transverse directions. This enhances tensile strength, transparency, and resistance to moisture and chemicals.

Unlike traditional woven bags, BOPP laminated bags provide a smooth surface that supports high-definition printing. This makes them ideal for businesses focused on branding and product presentation.

Key Characteristics of BOPP Bags

- High durability and tear resistance

- Excellent moisture protection

- Premium printing quality

- Lightweight and easy to handle

- Suitable for bulk and retail packaging

Why Are BOPP Bags Widely Used Across Industries?

BOPP bags are widely adopted due to their versatility and cost efficiency. They offer both functional and marketing advantages, making them suitable for multiple industries.

One of the main reasons for their popularity is their ability to protect products from external elements like humidity, dust, and contamination. At the same time, they help brands stand out on store shelves with vibrant and long-lasting prints.

Industries That Commonly Use BOPP Bags

- Agriculture (rice, wheat, seeds, fertilizers)

- Food & FMCG products

- Cement and construction materials

- Chemicals and minerals

- Animal feed and pet food

Types of BOPP Bags Based on Lamination

Lamination plays a vital role in determining the durability, appearance, and protection level of BOPP bags. Based on lamination, BOPP bags are primarily classified into two main types. Each type serves different packaging requirements depending on product sensitivity and storage conditions.

Understanding these Types of BOPP Bags helps businesses choose the right packaging solution for their specific applications.

Single-Side Laminated BOPP Bags

Single-side laminated BOPP bags have a BOPP film laminated on only one side of the woven fabric. This structure provides adequate strength while keeping packaging costs under control.

These bags are widely used where moderate protection and attractive printing are required. The laminated side carries high-quality graphics, while the non-laminated side allows breathability when needed.

Key Features:

- Cost-effective packaging solution

- Good print quality on one side

- Lightweight and easy to handle

Common Applications:

- Agricultural products

- Animal feed packaging

- Food grains and pulses

Both-Side Laminated BOPP Bags

Both-side laminated BOPP bags feature BOPP film laminated on both inner and outer surfaces. This offers enhanced protection against moisture, dust, and external damage.

These bags are ideal for products that require longer shelf life and better resistance during transportation and storage. They also provide superior strength and long-lasting print clarity.

Key Features:

- Maximum durability and moisture resistance

- Premium look and finish

- Improved product safety

Common Applications:

- Cement and construction materials

- Chemicals and fertilizers

- High-value food and FMCG products

Types of BOPP Bags Based on Printing Technology

Printing technology plays a major role in the visual appeal and branding effectiveness of BOPP bags. Different printing methods are used depending on design complexity, volume requirements, and budget.

These Types of BOPP Bags help businesses create strong brand recognition while maintaining packaging durability.

Rotogravure Printed BOPP Bags

Rotogravure printing is known for its superior image quality and color consistency. This technique allows high-definition graphics, sharp text, and vibrant colors that remain intact even under rough handling.

Rotogravure printed BOPP bags are commonly used by brands that prioritize premium packaging and long-term visual impact.

Key Benefits:

- Excellent print clarity and color depth

- Ideal for complex and multi-color designs

- Long-lasting print durability

Best Suited For:

- Branded food products

- FMCG packaging

- Export-quality BOPP bags

Flexographic Printed BOPP Bags

Flexographic printing is a cost-effective solution for large-volume packaging needs. While the print quality is slightly lower than rotogravure, it still delivers clear and consistent results for simpler designs.

This printing method is often chosen for industrial and agricultural packaging where functionality is more important than intricate graphics.

Key Benefits:

- Economical for bulk orders

- Faster production turnaround

- Suitable for simple branding

Best Suited For:

- Fertilizers and cement packaging

- Animal feed bags

- Industrial goods

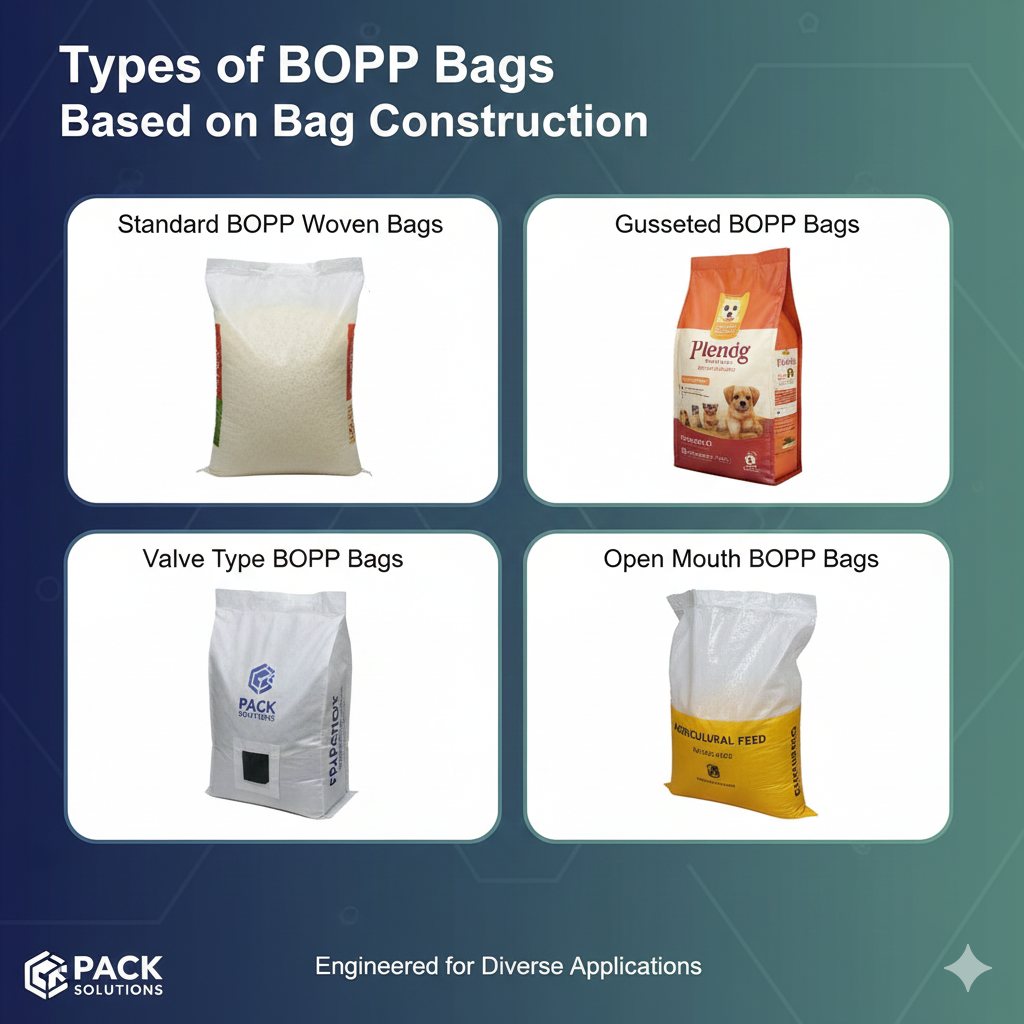

Types of BOPP Bags Based on Bag Construction

The construction of a BOPP bag determines its filling method, storage efficiency, and overall handling performance. Different construction styles are designed to meet specific industrial and commercial packaging needs.

Understanding these Types of BOPP Bags based on construction helps businesses improve packing speed, reduce product loss, and ensure safe transportation.

Standard BOPP Woven Bags

Standard BOPP woven bags are the most commonly used type in the packaging industry. They feature a simple open-mouth design that allows easy manual or machine filling.

These bags offer a balance between strength, cost, and visual appeal, making them suitable for a wide range of products.

Key Features:

- Durable woven polypropylene base

- Easy filling and sealing

- Available in multiple sizes and capacities

Common Applications:

- Rice, wheat, and food grains

- Sugar and salt packaging

- Industrial raw materials

Gusseted BOPP Bags

Gusseted BOPP bags come with side folds that expand when filled. This design increases storage capacity and provides better stability when stacked.

They are especially useful for products that require more volume without increasing bag height.

Key Features:

- Increased carrying capacity

- Better shelf and pallet stability

- Enhanced product presentation

Common Applications:

- Pet food and animal feed

- Agricultural produce

- Bulk food packaging

Valve Type BOPP Bags

Valve-type BOPP bags are designed for automated filling systems. These bags have a built-in valve that allows fast filling and automatically seals once the product is inside.

They are ideal for high-speed industrial packaging environments.

Key Features:

- Dust-free filling

- Faster packaging operations

- Consistent bag shape after filling

Common Applications:

- Cement and construction materials

- Chemicals and powdered products

Open Mouth BOPP Bags

Open mouth BOPP bags are designed for easy filling and flexible sealing options. They can be stitched, heat-sealed, or glued depending on the application.

These bags are widely used where manual filling is preferred.

Key Features:

- Easy handling and sealing

- Cost-effective construction

- Suitable for various sealing methods

Common Applications:

- Agricultural and food products

- Fertilizers and minerals

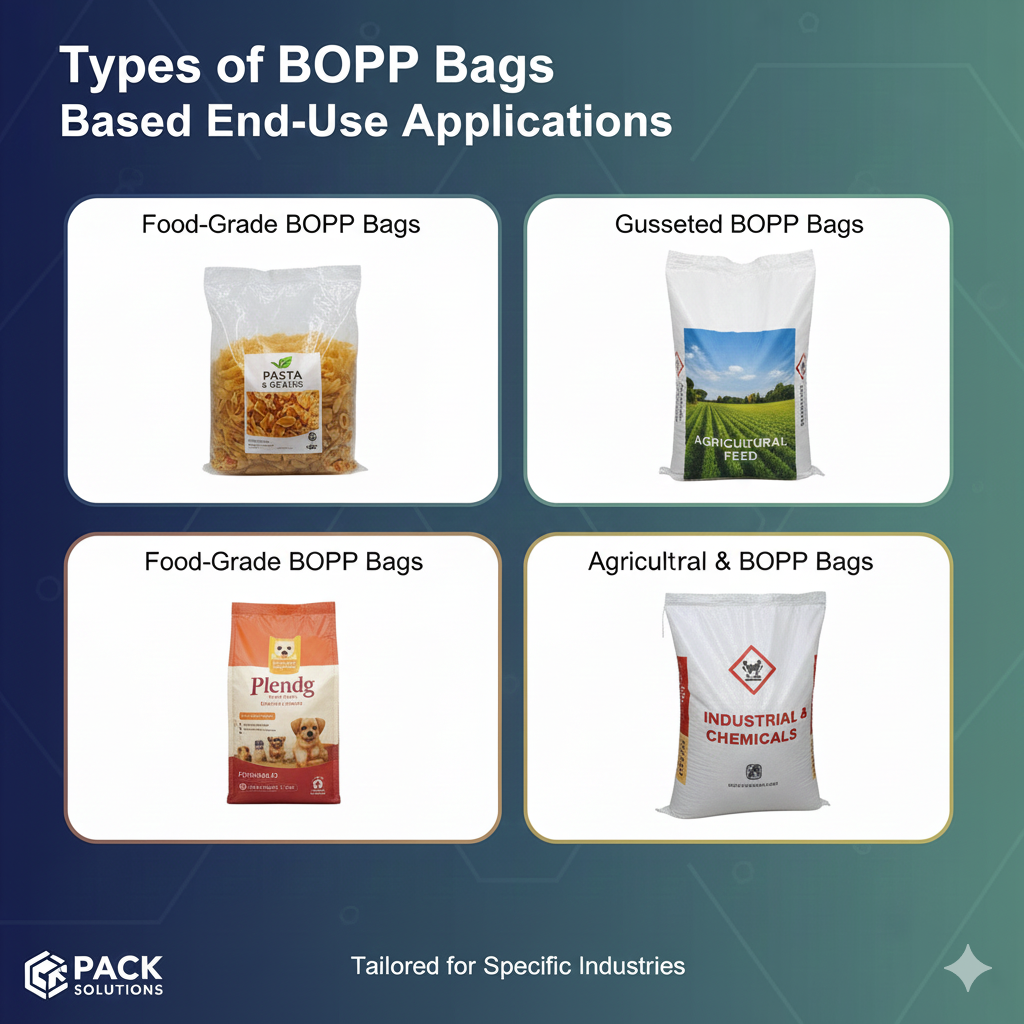

Types of BOPP Bags Based on End-Use Applications

Different industries have unique packaging requirements related to safety, durability, and compliance. Based on their application, BOPP bags are designed to meet specific performance and regulatory needs.

Choosing the right Types of BOPP Bags according to end-use ensures product protection, longer shelf life, and efficient logistics.

Food-Grade BOPP Bags

Food-grade BOPP bags are manufactured using high-quality raw materials that comply with food safety standards. These bags prevent contamination and help maintain freshness during storage and transportation.

They also support attractive branding, which is essential for consumer-facing food products.

Key Features:

- Hygienic and contamination-free

- Moisture and odor resistance

- High-quality food-safe printing

Common Applications:

- Rice, flour, sugar, and pulses

- Snacks and dry food items

Agricultural BOPP Bags

Agricultural BOPP bags are designed to withstand rough handling and varying weather conditions. They provide excellent protection against moisture, pests, and UV exposure.

These bags help preserve product quality from farm to market.

Key Features:

- Strong tensile strength

- UV-stabilized for outdoor storage

- Tear and puncture resistance

Common Applications:

- Seeds and fertilizers

- Grains and animal feed

Industrial & Chemical BOPP Bags

Industrial and chemical BOPP bags are built for heavy-duty applications. They are engineered to handle abrasive and powdered materials safely while minimizing spillage and contamination.

These bags often include anti-slip coatings and reinforced seams for added safety.

Key Features:

- High load-bearing capacity

- Chemical and moisture resistance

- Safe stacking and transportation

Common Applications:

- Cement and construction materials

- Chemicals and minerals

What Are the Benefits of Using Different Types of BOPP Bags?

BOPP bags offer more than just basic packaging. Their advanced structure and customization options provide multiple benefits across storage, transportation, and branding.

Selecting the right Types of BOPP Bags helps businesses improve product safety while enhancing market visibility.

Enhanced Product Protection

BOPP bags offer excellent resistance to moisture, dust, and external contaminants. This ensures that products remain safe and intact throughout the supply chain.

Their strong woven base reduces the risk of tearing, even during long-distance transportation.

Superior Branding and Shelf Appeal

One of the biggest advantages of BOPP bags is their high-quality printing surface. Businesses can showcase logos, product information, and vibrant designs that attract customer attention.

This makes BOPP bags an effective marketing tool at the point of sale.

Cost-Effective Packaging Solution

Despite their premium appearance, BOPP bags are cost-efficient for bulk packaging. Their durability reduces product loss, resulting in long-term savings for manufacturers and distributors.

Versatility Across Industries

From food and agriculture to cement and chemicals, BOPP bags adapt to various packaging needs. Their customizable size, structure, and printing make them suitable for multiple applications.

How to Choose the Right Type of BOPP Bag for Your Business?

Choosing the correct BOPP bag is essential for protecting your product and maintaining brand reputation. With multiple Types of BOPP Bags available, businesses should evaluate a few key factors before making a decision.

Consider Product Weight and Volume

The weight and size of the product determine the strength and construction of the BOPP bag. Heavy or bulk products require reinforced woven fabric and strong lamination.

Lightweight goods may only need single-side laminated bags.

Evaluate Storage and Transportation Conditions

If products are stored in humid or outdoor environments, moisture-resistant and UV-stabilized BOPP bags are recommended. For long-distance transport, durability and seam strength become critical.

Focus on Branding and Printing Needs

Businesses aiming for strong shelf presence should opt for high-quality rotogravure printed BOPP bags. Clear branding helps products stand out in competitive markets.

Check Industry Compliance Requirements

Food-grade products require hygienic materials and compliance with safety standards. Industrial products may need anti-slip coatings or valve-type construction for safe handling.

Balance Quality and Budget

While premium BOPP bags offer better performance, selecting the right type based on actual needs helps optimize costs without compromising quality.

Are BOPP Bags Environment-Friendly?

BOPP bags are considered more environmentally responsible compared to many traditional plastic packaging options. They are made from polypropylene, a material that is fully recyclable and widely reused across industries.

With proper waste management and recycling systems, BOPP bags can be reprocessed into new plastic products, reducing landfill impact.

Modern manufacturers also focus on reducing material usage while maintaining strength. This helps lower the overall carbon footprint during production and transportation.

Sustainability Advantages of BOPP Bags

- 100% recyclable polypropylene material

- Lightweight design reduces transportation emissions

- Long lifespan reduces frequent replacement

- Supports reuse in multiple applications

As sustainability becomes a priority, many Types of BOPP Bags are now produced using eco-conscious manufacturing practices.

Which Industries Benefit the Most from Different Types of BOPP Bags?

BOPP bags are highly versatile, making them suitable for a wide range of industries. Their durability, visual appeal, and customization options allow businesses to meet both functional and branding requirements.

Different Types of BOPP Bags are tailored to suit the needs of specific sectors.

Food and FMCG Industry

The food sector benefits greatly from food-grade BOPP bags due to their hygiene, moisture resistance, and attractive presentation. High-quality printing helps build consumer trust and brand recognition.

Agriculture Sector

Agricultural products require strong packaging that can withstand outdoor storage and rough handling. BOPP bags with UV stabilization and high tensile strength are ideal for grains, seeds, and fertilizers.

Cement and Construction Industry

Valve-type and heavy-duty BOPP bags are widely used in the cement and construction sector. These bags support automated filling and provide excellent strength for transporting heavy materials.

Chemical and Industrial Sector

Chemical products need packaging that prevents leakage and contamination. Industrial-grade BOPP bags offer chemical resistance and secure sealing for safe handling.

Animal Feed and Pet Food Industry

Gusseted and laminated BOPP bags help maintain product freshness while offering stable stacking and premium shelf appeal.

BOPP Bags vs Other Packaging Solutions

When selecting the right packaging, businesses often compare BOPP bags with other commonly used materials. Understanding how BOPP bags perform against alternative solutions helps highlight why the various Types of BOPP Bags are widely preferred across industries.

BOPP Bags vs Paper Bags

Paper bags are often seen as eco-friendly, but they lack the strength and moisture resistance required for heavy or bulk products. BOPP bags, on the other hand, offer superior durability and protect contents from humidity and tearing. This makes them more suitable for products such as grains, fertilizers, and construction materials.

BOPP Bags vs Jute Bags

Jute bags are biodegradable and reusable, but they are heavier, more expensive, and offer limited printing options. BOPP bags provide a lighter and more cost-effective alternative while delivering excellent print quality for branding. They also offer better resistance to moisture, which is essential for product preservation.

BOPP Bags vs Plastic Sacks

Traditional plastic sacks may be inexpensive, but they lack structural strength and visual appeal. BOPP bags combine a woven polypropylene base with laminated film, resulting in higher load-bearing capacity and a professional appearance. This makes BOPP bags ideal for both industrial use and retail packaging.

Overall, BOPP bags offer a balanced solution by combining strength, protection, branding potential, and cost efficiency. These advantages explain why businesses increasingly choose different Types of BOPP Bags over conventional packaging options.

Why Choose Oberon Polypack for BOPP Bags?

When it comes to reliable and high-quality BOPP packaging, choosing the right manufacturer is just as important as selecting the right bag type. Oberon Polypack is a trusted name in the packaging industry, offering customized and export-quality BOPP bag solutions.

With years of manufacturing expertise, Oberon Polypack understands the diverse packaging needs of industries across food, agriculture, construction, and chemicals.

Proven Manufacturing Expertise

Oberon Polypack uses advanced production techniques and strict quality control processes to ensure consistent strength, durability, and finish in every BOPP bag.

Customization and Printing Excellence

From size and capacity to high-definition printing, Oberon Polypack offers complete customization. Businesses can choose from various Types of BOPP Bags to match their branding and functional requirements.

Quality and Compliance Standards

All BOPP bags are manufactured using premium-grade polypropylene materials. Food-grade and industrial compliance requirements are carefully followed to ensure product safety.

Reliable Bulk Supply and Export Capability

Oberon Polypack supports large-volume orders with timely delivery. Their packaging solutions are designed to meet both domestic and international quality standards.

Future Trends in BOPP Bag Packaging

The packaging industry is evolving rapidly, and BOPP bags are adapting to meet changing market and sustainability demands. Innovations in material technology and printing are shaping the future of BOPP packaging.

One major trend is the growing focus on sustainable packaging solutions. Manufacturers are working to reduce material usage while maintaining strength and durability. Lightweight BOPP bags with high performance are becoming increasingly popular.

Another emerging trend is advanced printing technology. Brands are investing in sharper graphics, matte and glossy finishes, and enhanced color consistency to improve shelf appeal.

Customization is also gaining importance. Businesses now prefer tailor-made Types of BOPP Bags designed specifically for their product size, industry standards, and branding goals.

Conclusion

BOPP bags have become an essential packaging solution across industries due to their strength, versatility, and premium appearance. Understanding the different Types of BOPP Bags helps businesses make informed decisions that protect products and enhance brand value.

From lamination and printing methods to construction and end-use applications, each type of BOPP bag serves a specific purpose. Selecting the right option ensures better product safety, improved logistics, and stronger market presence.

For businesses looking for reliable, high-quality, and customized BOPP packaging, Oberon Polypack offers solutions that meet industry standards and evolving market needs. Choosing the right packaging partner can make a lasting difference in both performance and brand perception.

People Also Ask (FAQs)

What are BOPP bags used for?

BOPP bags are used for packaging products such as food grains, rice, wheat, sugar, cement, fertilizers, chemicals, and animal feed. Their strength, moisture resistance, and high-quality printing make them suitable for both industrial and retail packaging.

How many types of BOPP bags are available?

There are several Types of BOPP Bags, including single-side laminated, both-side laminated, gusseted bags, valve-type bags, open mouth bags, food-grade BOPP bags, and industrial BOPP bags. Each type is designed for specific applications and handling requirements.

What is the difference between laminated and non-laminated BOPP bags?

Laminated BOPP bags have a protective BOPP film layer that improves moisture resistance, durability, and print quality. Non-laminated bags are more basic and offer less protection and visual appeal compared to laminated BOPP bags.

Are BOPP bags suitable for food packaging?

Yes, food-grade BOPP bags are safe for food packaging when manufactured using approved raw materials and hygienic processes. They are commonly used for rice, flour, pulses, sugar, and other dry food products.

Which type of BOPP bag is best for cement packaging?

Valve-type and both-side laminated BOPP bags are best suited for cement packaging. These bags support automated filling, prevent dust leakage, and provide high strength for handling heavy loads.

Are BOPP bags recyclable?

Yes, BOPP bags are made from polypropylene, which is 100% recyclable. When collected and processed properly, they can be reused to manufacture other plastic products, making them a more sustainable packaging option.

How do I choose the right BOPP bag for my product?

To choose the right BOPP bag, consider product weight, storage conditions, moisture exposure, branding needs, and industry compliance. Selecting the correct type ensures better protection, cost efficiency, and brand presentation.

Can BOPP bags be customized with branding?

Yes, BOPP bags can be fully customized with high-quality printing, brand logos, product details, and color designs. Advanced printing techniques help businesses enhance shelf appeal and brand recognition.

Why are BOPP bags better than traditional PP woven bags?

BOPP bags offer better moisture resistance, superior print quality, and a premium appearance compared to traditional PP woven bags. They provide added value through durability and branding benefits.

Who is a reliable manufacturer of BOPP bags in India?

Oberon Polypack is a reliable manufacturer and supplier of high-quality BOPP bags, offering customized packaging solutions for food, agriculture, industrial, and export markets.

.png)